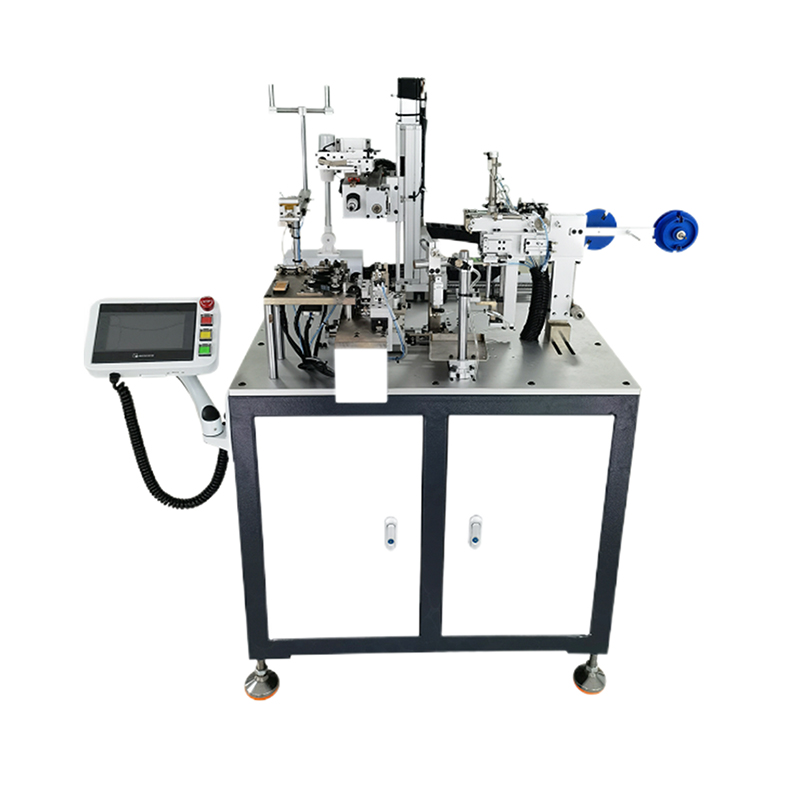

Key Features:

- Single-Shaft Precision: Equipped with a high-speed single shaft capable of both clockwise and counterclockwise rotations (360° per cycle), ensuring precise and consistent winding.

- High-Speed Operation: Spindle speed up to 4000 rpm for efficient production.

- 3D Motion Range: Supports a 3D motion range of X: 400mm, Y: 200mm, and Z: 120mm for complex and flexible assembly tasks.

- Wide Wire Compatibility: Handles wire diameters ranging from 0.03mm to 1.0mm, including multi-core wires up to 0.1mm x 50 cores.

- Customizable Control: Features a 12-axis programmable motion control system for optimized and tailored performance.

Advanced Functionality:

- Automated Material Handling: Supports vibration plate feeding, wire joint feeding, manual full-line feeding, and automatic discharging for enhanced workflow efficiency.

- Inter-Device Integration: Compatible with single or multiple linked machine operations for scalable production setups.

- Energy Efficient: Operates at a total power of 2500W, ensuring optimal energy consumption.

- Compact Design: Dimensions of 800mm x 650mm x 1350mm make it a space-efficient addition to your production line.

- Lightweight and Sturdy: Weighs approximately 300kg, providing stability and portability.

Technical Specifications:

- Spindle Power: 400W.

- Quick Tool Connector Diameter: 10mm for efficient and fast tool changes.

- Power Supply: AC 220V ±10%.

- Pneumatics: Requires air pressure between 0.4 MPa and 0.6 MPa.

Premium Components:

- Motion Controller: Guangdong Junyi for advanced control and customization.

- Power Supply: Mingwei for stable and reliable energy delivery.

- Bearings and Guides: NSK (Japan) and TBI (Taiwan) ensure smooth operation and durability.

- Sensors and Switches: High-quality components from Panasonic (Japan) and Yadeke (Taiwan) for safety and precision.

- Belts: Premium Mitsuboshi belts (Japan) for long-lasting performance.